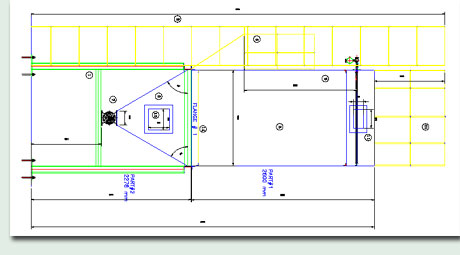

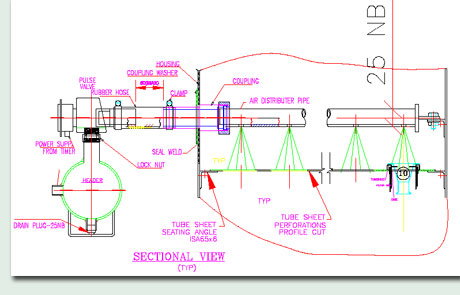

Pulse Jet Bag Filter

Pulse Jet Bag Filter

|

Green Star APC Tech Private Limited

has developed a superior design of Pulse Jet Bag

Filter System with many advantages over existing

system designs available in the market. Salient

features of GST designed Bag Filter Systems are

as follows |

|

-

High Filtration

efficiency of Bag Filter system (upto 99.5%)

thus superior emission norms (15-50 mg/Nm3).

-

Low pressure drop

across Bag Filter system (80-150 mmWC).

-

Low power consumption of ID Fan due to low DP across Bag Filter system.

-

Use of double diaphragm solenoid valves ensure effective cleaning of Filter Bags.

-

Proper design of Bag Filter system, Hopper Angle and other critical aspects results in effective dust collection and removes possibilities of dust re-entrapment.

-

Longer life of Filter Bags, Cages and other accessories thus lower cost of operation.

-

Efficient working of Bag Filter system reduces requirement of maintenance.

-

Bag Filter systems designed for use in sub micron particle collection.

-

We use Filter Media with suitable chemical and mechanical finish to enhance performance of Filter Bags thus better & easy particulate collection from hopper.

-

Ultra modern electronic devices are used to measure and control various process parameters (pressure, temperature, flow, accumulation etc) of Bag Filter system thus assist in easy control during operation.

-

We can design Pulse Jet Bag Filter system upto 100000 m3/hr suitable for upto 260 Deg C for dust/fumes with acid/alkali content and fine micron sticky dust. Bag Filter systems can be supplied in MS/SS-304/SS-316-L to meet application requirement.

We can provide the Bag Filter system with

“On-Line” and “Off-Line” cleaning arrangement to

suite your application requirement and meet

stringent pollution control norms. Please write

to us for same and our Sales Engineer shall be

glad to assist you here with technical

inputs.

Top

|

|

Reverse Air Bag

House

Reverse Air Bag

House

|

Situations demanding high gas volume (more than 100000 m3/hr) necessitates use of a different technology, Reverse Air Bag House with Filter Bags being cleaned using counter flow of Gases from opposite direction. This systems are largely used world over in various applications like Cement Kiln, Large Boilers in Power Plants, Fumes Extractions in Steel industry etc. We can undertake the complete project on turn key basis thus saving your precious time with efficient on-time execution of project. |

|

Top |

|

Cartridge Filter System

Cartridge Filter System

|

We can design compact dry air

Filtration System using pleated cartridge

elements thus resulting in space and cost

savings at the same time delivering effective

filtration performance. We have supplied

numerous Cartridge Filter System using Pulse Jet

technology for various applications and gas

volumes ranging from 500 m3/hr to 10000 m3/hr.

These units are custom designed to meet the site

constraints and application

requirement. |

|

Top

Silo Vent Filter

Silo Vent Filter

|

We can supply Bag Filter

systems designed for venting application of a

Silo / Material Storage Tank thus assisting in

efficient collection of valuable process dust

and effective performance of material handling

chutes in depositing dust in the Silo. These

systems are also custom designed to meet the

application requirement as per dust

characteristics. |

| |

|

Top

|

|

Material Dump System

Material Dump System

|

Modern technology enables clean

working environment. We can design Manual

Material Dump systems to meet your specific

requirement as per process layout. We have

supplied such system with low noise levels and

effective dust collections to enable better work

place situations for your invaluable employee

resource. |

|

Top

Cyclone/Multi Cyclone

Cyclone/Multi Cyclone

|

Applications where cost

economies do not permit use of Bag Filter system

for dust collection, we can design and supply

the cost efficient Cyclones for dust collection

application. These systems can be designed for

wide ranging gas volume (1000 m3/hr to 50000

m3/hr) and heave to medium dust with acid

traces. High efficiency Multi Cyclones can be

supplied for meeting stringent application and

pollution control requirement. |

|

Top

|

|

Wet Scrubber

Wet Scrubber

|

For dust

with high moisture and traces of acidic content,

we suggest use of Wet Scrubber to effectively

control Pollution and dust

collection. These system utilizes use of

water spray in collecting the dust while

passing through narrow ventury orifice. Whole system

is designed with the perspective of probable acid

attack on body of system, thus critical

and contact parts being made in

SS-316. |

|

Top

|

|

Heat Exchanger

Heat Exchanger

|

We have expertise to design Heat Exchanges meeting

various application needs across

range of material of construction ranging

from Carbon Steel to Alloy Steel to

AISI 304/316. Our Technical Team shall be

readily available to visit your plant and study

the process parameters for design of suitable

Heat Exchanger of Tube & Shell

type. |

|

Top

|

|

Filter Bags

Filter Bags

|

Filter

Bags are a

crucial part in the Bag Filter system and

its performance decides the efficiency of system to

a large extent. Use

of right Filter Media with suitable

performance enhancement finish (mechanical and chemical) results

in longer life of Filter Bags, Lower

DP across Bag Filter and high Filtration Efficiency.

WE can supply Filter Bags made of

following Filter Media to meet your

requirement. |

|

|

|

Low Temperature |

: |

Polyester / Polypropylene / Homopolymer

Acrylic (PAN-H) |

|

Medium Temperature |

: |

Ryton (PPS), Nomex,

Aramid/Meta Aramid |

|

High Temperature |

: |

P-84 (PI),

Woven/Nonwoven Fibre Glass, 100% PTFE |

|

PTFE Membrane Laminated |

: |

on PE/PP/PPS/Acid

Resistant Fibre Glass/100% PTFE |

|

Chemical Finishes |

: |

Silicon, Graphite, Teflon |

|

Mechanical Finishes |

: |

Anti Static, Singed,

Calendared, Spark Resistant |

|

Filter Bag Type |

: |

Pulse Jet, RABH Fibre

Glass Filter

Bags |

|

|

We have exclusive arrangement

with world leader in Filtration Business, M/s

Midwesco Filter Resources Inc USA to supply

their products in Indian market. We welcome your

valuable inquiry towards these

products.

|

Top

|

|

Pulse Jet Bag Filter

Accessories

Pulse Jet Bag Filter

Accessories

|

We have extensive know how on

various components being used

in Pulse Jet Bag Filter systems

and its suitability to your earlier supplied

system. We can assist you in choosing

right material of construction and suitable dimensions to

meet stringent pollution norms. We can supply

following material to meet your replacement

requirement. |

|

|

|

Cages |

: |

Carbon Steel / AISI 304 /

AISI 316-L / 10 to 24 wire in

3-4 mm |

|

Ventury |

: |

Cast Iron, Aluminum with

suitable groove for

Cage fitment |

|

Solenoid Valves |

: |

Single,

Double Diaphragm in 1/1.5/2 inches |

|

Timer Card |

: |

Suitable for

3 to 30 channel |

|

RALV |

: |

200 to 450 mm,

square/circular flange, CS/SS-304/SS316L |

|

Screw Conveyor |

: |

500 to

6000 mm. CS/SS-304/SS316L |

|

ID Fan |

: |

Upto 450000 m3/hr, centrifugal backward

curved inclined

etc |

|

By-Pass Dampers |

: |

For complete system By-Pass in event

of temperature

excursions |

|

System

Automation |

: |

For ease of control during

operation of

unit |

|

Top

|

|

Reverse Air Bag House

Accessories

Reverse Air Bag House

Accessories

|

Green Star APC Tech Private Limited

has wide experience in working with ESP

technology through its various associates. We have

thorough experience in selecting suitable components for ESP

of major manufacturers. We can supply following

accessories manufactured in our strict quality

control.

-

Pneumatic Tensioning

Device

-

-

-

-

|

|

Top

|

|

ESP Accessories

ESP Accessories

|

Green Star APC Tech Private Limited

has wide experience in working with ESP

technology through its various associates. We have

thorough experience in selecting suitable components for ESP

of major manufacturers. We can supply following

accessories manufactured in our strict quality

control.

-

Collecting Plates / Discharge

Electrodes

-

Shaft / Support

InsulatorsConical SS Spring

-

TR Set (of suitable rating)

-

|

|

Top

|